From Lean to Digital Transformation: The Evolution of Supplier Quality Engineering in Mexico

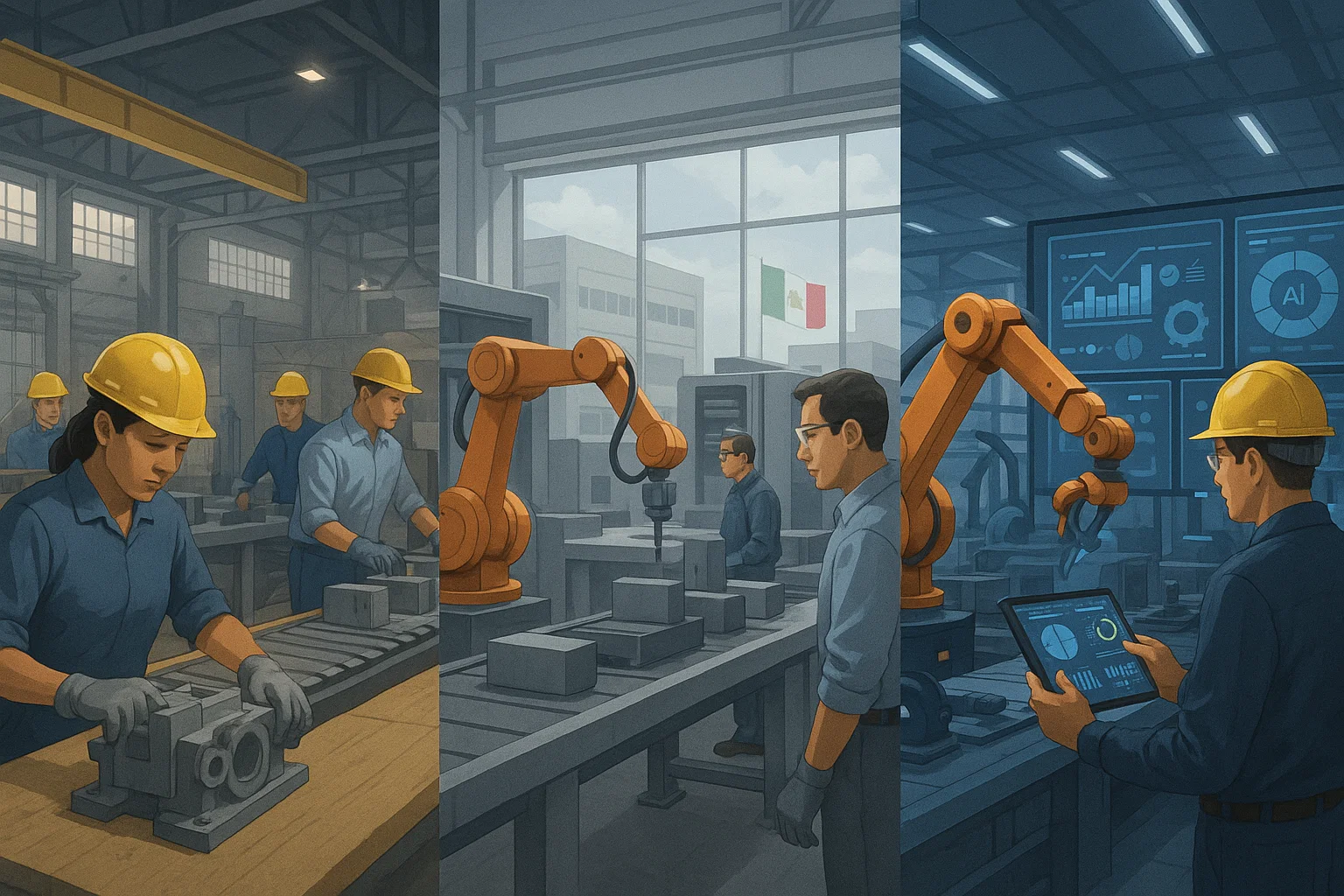

Supplier Quality Engineering in Mexico has undergone a powerful transformation. What began as Lean-based practices focused on waste reduction and efficiency has now merged with digital tools like AI, IoT, and digital twins. The shift from Lean to Digital Transformation has redefined how suppliers operate, meet global standards, and strengthen manufacturing performance. Mexican industries are adopting smart systems that provide real-time data, predictive quality insights, and automation. This article explores the journey from traditional Lean foundations to today’s digital-first supplier quality strategies and highlights how companies can thrive by embracing both.

The Lean foundation of supplier quality in Mexico

For decades, Lean manufacturing shaped supplier quality across Mexico’s industrial landscape. Automotive, aerospace, and electronics companies introduced Lean to cut waste, improve consistency, and strengthen customer satisfaction.

Core principles of Lean

Lean practices focused on:

- Continuous improvement (Kaizen) – Encouraging employees to solve problems daily.

- Eliminating waste – Reducing downtime, defects, and unnecessary processes.

- Quality at the source – Empowering workers to detect issues early.

- Value stream mapping – Identifying inefficiencies in supplier processes.

Supplier quality in the Lean era

Suppliers were expected to meet strict metrics using tools like:

- APQP (Advanced Product Quality Planning) for structured planning.

- FMEA (Failure Mode and Effects Analysis) to assess risks.

- SPC (Statistical Process Control) to monitor variations.

- PPAP (Production Part Approval Process) for verifying supplier readiness.

These Lean-driven methods gave Mexico a reputation as a reliable global supplier, particularly in automotive and electronics.

The shift: Lean meets digital transformation

As manufacturing advanced, Lean methods alone were no longer enough. Global supply chains demanded faster responses, zero tolerance for defects, and complete transparency. This pushed Lean to evolve into Digital Lean, combining traditional practices with cutting-edge technology.

What Digital Lean means

Digital Lean does not replace Lean—it enhances it. It keeps the focus on efficiency and customer value but uses technology to achieve results faster and more accurately.

Key enablers include:

- IoT sensors to collect real-time process data.

- Artificial intelligence (AI) to predict and prevent quality issues.

- Automation to speed up inspections and reduce errors.

- Cloud platforms for supplier data integration and analytics.

Why Mexico is embracing Digital Lean

Mexico’s role as a nearshoring hub requires precision and agility. With U.S. companies sourcing locally to strengthen resilience, suppliers must combine Lean discipline with digital tools to stay competitive.

Digital trends reshaping Supplier Quality Engineering in Mexico

Real-time monitoring with IoT

Connected devices track conditions like temperature, vibration, and pressure. This data allows immediate responses when quality risks appear.

AI-driven predictive quality

Machine learning analyzes production data to forecast possible defects. Teams act early, preventing large-scale issues.

Digital twins for supplier operations

Virtual models replicate supplier processes. Engineers can test changes digitally, saving time and money.

Automated inspections

Vision systems and robotics detect micro-defects at speeds no human can match. These technologies improve consistency and reduce inspection costs.

Blockchain-enabled traceability

Blockchain secures supplier records, certifications, and part histories. This builds trust with buyers and prevents fraud.

Case examples of Lean to Digital evolution in Mexico

Automotive industry

Mexican automotive suppliers blend Lean assembly methods with AI-powered predictive maintenance. This reduces downtime and keeps production lines running smoothly.

Aerospace suppliers

In aerospace, precision is everything. Suppliers use IoT sensors and blockchain to meet global certification standards while reducing compliance risks.

Electronics manufacturing

Electronics plants use robotic vision systems for component inspection. Combined with Lean quality gates, this ensures micro-level accuracy.

Medical devices and pharma

Pharmaceutical suppliers apply IoT for cold chain monitoring and AI for regulatory compliance. This strengthens both product safety and supplier credibility.

Challenges in digital adoption

Transitioning from Lean to Digital Lean is not without obstacles.

- High investment costs – Advanced sensors and AI systems require upfront capital.

- Skills gap – Many suppliers lack digital expertise.

- Legacy systems – Older equipment may resist integration.

- Cybersecurity risks – More connectivity creates new vulnerabilities.

Practical solutions

- Start with pilot programs on one supplier process.

- Provide training and upskilling in data and analytics.

- Retrofit existing machines with smart sensors.

- Invest in cybersecurity protocols to protect sensitive data.

How Mexico’s industrial landscape supports digital supplier quality

Mexico’s manufacturing hubs—Querétaro, Nuevo León, and Baja California—are rapidly modernizing. Incentives for Industry 4.0 adoption and skilled labor pools are fueling change. Nearshoring trends add pressure but also create opportunities. By merging Lean with digital, Mexican suppliers position themselves as trusted, globally competitive partners.

Practical steps for companies moving from Lean to Digital

- Assess current Lean practices – Identify strengths and gaps in existing systems.

- Define digital priorities – Choose technologies that directly enhance supplier quality.

- Pilot small projects – Prove ROI before scaling.

- Build digital infrastructure – Invest in data platforms, AI tools, and IoT.

- Integrate Lean and digital – Use data to refine continuous improvement.

- Expand gradually – Roll out solutions across the supply chain.

Strengthening supplier relationships through digital tools

Digital tools make quality visible in real time. Buyers and suppliers share dashboards, reducing disputes and encouraging collaboration. Instead of pointing out failures after the fact, suppliers can take proactive action. For companies seeking expert support, Supplier Quality Engineering in Mexico provides tailored strategies to merge Lean foundations with modern digital tools.

Frequently Asked Questions (FAQs)

1. What is Digital Lean in supplier quality?

It’s the integration of Lean methods with digital tools like AI and IoT.

2. Why does Mexico need digital supplier quality now?

Nearshoring and global supply demands require faster, more reliable quality control.

3. Can small suppliers afford digital tools?

Yes. Affordable sensors and modular systems make adoption realistic even for small companies.

4. Do Lean methods still matter?

Absolutely. Lean remains the foundation. Digital systems enhance, not replace, Lean practices.

5. How do digital tools improve compliance?

Automated systems create traceable records, reducing audit risks and ensuring international certifications.

6. What is the future beyond 2030?

Expect AI-driven autonomous quality systems, blockchain supply chains, and AR-enabled inspections.

Conclusion

Supplier quality engineering in Mexico has come a long way. Lean principles built the foundation for efficiency and waste reduction. Now, digital technologies—AI, IoT, digital twins, and automation—are driving supplier quality into the future. By combining Lean’s proven methods with advanced digital tools, Mexican suppliers achieve higher consistency, lower costs, and stronger compliance.