Introduction

The oil and gas sector in Dubai is known for its rigorous operational standards and challenging environmental conditions. From offshore rigs to onshore processing facilities, every component must withstand extreme pressure, corrosion, and constant wear and tear. One small but crucial element in this high-stakes industry is the fastener. Among these, stud bolts play an integral role, ensuring structural integrity, safety, and efficiency across countless applications.

Selecting the right type of fasteners is not just a technical choice—it can significantly impact operational efficiency, maintenance costs, and overall project success. In the UAE’s competitive oil and gas landscape, businesses are increasingly seeking reliable, high-quality stud bolts to meet stringent industry demands.

What Are Stud Bolts?

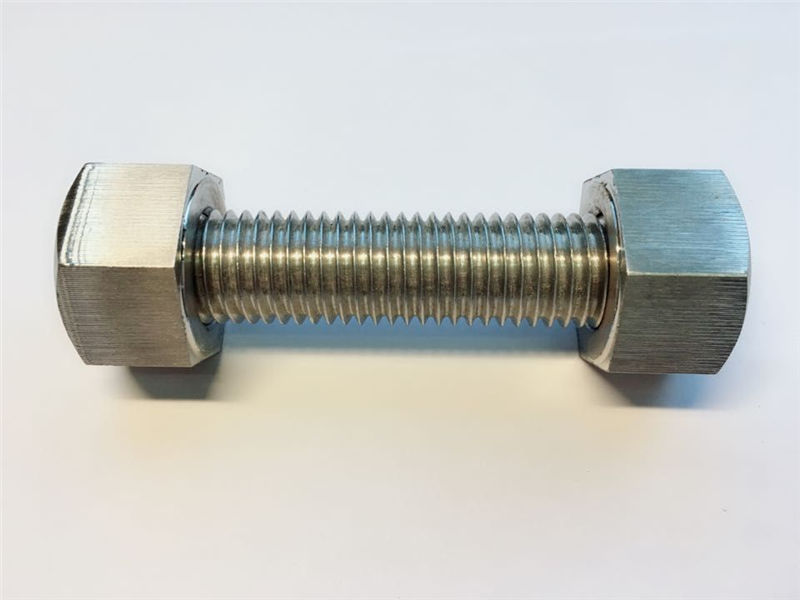

Stud bolts are threaded fasteners designed for heavy-duty applications, typically used to join flanges, pipelines, valves, and machinery in industrial settings. Unlike traditional bolts, a stud bolt is threaded on both ends and does not have a head. This design allows for more uniform stress distribution and the ability to use nuts on both ends to secure components tightly.

Their robust design makes them ideal for oil and gas installations, where high-pressure systems demand maximum reliability. Additionally, stud bolts often undergo specialized treatments, such as galvanization or heat treatment, to enhance corrosion resistance, making them well-suited for Dubai’s challenging coastal and desert environments.

Key Benefits of Stud Bolts in Dubai’s Oil & Gas Sector

1. Superior Strength and Durability

Stud bolts are engineered to withstand high tensile loads, ensuring connections remain secure even under extreme pressure. In oil and gas applications, where pipelines and flanges operate under thousands of PSI, the reliability of stud bolts is essential.

The material quality—often high-grade stainless steel or alloy steel—ensures resistance against mechanical stress, fatigue, and potential deformation. This strength guarantees minimal maintenance requirements and reduces the risk of operational downtime due to fastener failure.

2. Enhanced Corrosion Resistance

Dubai’s oil and gas installations are frequently exposed to saltwater, high humidity, and harsh chemical environments. Stud bolts provide excellent resistance to corrosion, particularly when manufactured with specialized coatings or stainless steel.

By reducing corrosion risks, stud bolts help maintain the integrity of pipelines, valves, and equipment over time. This directly translates into longer service life, fewer replacements, and decreased operational costs for oil and gas companies.

3. Reliable Sealing for High-Pressure Systems

In high-pressure oil and gas pipelines, leaks can be catastrophic. Stud bolts ensure tight flange connections, providing reliable sealing capabilities under intense operational conditions.

The uniform clamping force achieved through the double-ended threaded design minimizes the likelihood of leaks, helping maintain system efficiency and safeguarding both personnel and infrastructure. For Dubai’s industrial pipelines, where safety and compliance are paramount, this reliability is invaluable.

4. Ease of Installation and Maintenance

Stud bolts offer significant advantages in terms of installation. Because they are threaded on both ends, they can be easily fitted into flanges or machinery, allowing technicians to secure nuts from either side.

This design facilitates efficient assembly and disassembly during maintenance or equipment replacement. In fast-paced oil and gas operations in Dubai, reducing downtime is critical. Stud bolts simplify repairs and inspections, improving workflow and ensuring projects stay on schedule.

5. Adaptability to Various Industrial Applications

One of the main reasons stud bolts are preferred in Dubai’s oil and gas sector is their versatility. They are suitable for a wide range of applications, including pipelines, pressure vessels, compressors, heat exchangers, and structural supports.

The availability of different grades, lengths, and diameters allows engineers to select the perfect stud bolt for any scenario. This flexibility ensures compatibility with both new installations and retrofitting projects, making stud bolts a go-to fastener for engineers across the industry.

Note : Searching for reliable Stud Bolts in Dubai? Oman Ocean Trading LLC supplies premium, certified bolts for construction, oil, and gas industries. With fast delivery and exceptional quality, we help you maintain project timelines and efficiency. Contact Oman Ocean Trading LLC today to source the best fasteners.

6. Cost-Effectiveness Over Time

While high-quality stud bolts may have a higher upfront cost compared to standard fasteners, their durability, reduced maintenance needs, and extended lifespan make them cost-effective in the long run.

Fewer replacements, minimized downtime, and reduced risk of leaks or failures translate to lower operational costs. For companies operating in Dubai’s high-demand oil and gas environment, investing in reliable fasteners is not an expense—it’s a strategic decision that protects both capital and productivity.

How to Choose the Right Stud Bolts

Selecting the right Stud Bolts in Dubai requires careful consideration of the application, pressure rating, material grade, and environmental conditions. Here are some essential factors:

- Material Grade: Ensure compatibility with operating conditions; stainless steel and alloy steel are commonly used for high-pressure and corrosive environments.

- Thread Type and Size: Match with flanges and machinery for optimal clamping force.

- Coating or Treatment: Galvanization, plating, or heat treatment improves corrosion and wear resistance.

- Compliance and Certification: Choose bolts that meet international standards such as ASTM, DIN, or API to guarantee quality and safety.

Working with a certified supplier ensures access to high-quality stud bolts with proper documentation, traceability, and post-sale support.

Industry Examples in Dubai

Many oil and gas facilities in Dubai rely on stud bolts for critical operations. Offshore rigs utilize corrosion-resistant bolts to secure structural supports exposed to seawater, while refineries employ them to join high-pressure piping systems.

By prioritizing reliability and long-term performance, engineers can prevent costly downtime and avoid hazardous leaks or failures. Stud bolts are also commonly used in joint assemblies for pipelines, compressors, and high-pressure vessels, proving their indispensable role across the sector.

Also Read : Enrollment Trends Reveal Rising Demand for Nearby Childcare in JVC

Conclusion

Stud bolts are small but mighty components that form the backbone of Dubai’s oil and gas infrastructure. Their superior strength, corrosion resistance, and reliability make them essential for high-pressure, high-stakes applications. Beyond operational performance, they offer ease of installation, adaptability, and long-term cost savings.

For businesses operating in Dubai, sourcing quality Stud Bolts in Dubai from certified suppliers ensures compliance with international standards, reduces maintenance challenges, and safeguards personnel and equipment. In an industry where every connection counts, investing in the right fasteners is not just practical—it’s critical.

By understanding the benefits and carefully selecting the right products, oil and gas companies can maintain safe, efficient, and productive operations while minimizing risk and cost.